Material regeneration

Classification

Solution

Product Accessories

A high-tech enterprise engaged in new energy materials, closely following the market development trend and meeting the diversified needs of customers, has established a more comprehensive research and development, production and sales system of lithium battery materials.

Product Details

Enterprise Introduction

Anhui Patrol Eagle Renewable Resources Utilization Co., Ltd.Founded on November 12, 2018 with a registered capital of 50 million yuan, it is located at 500 Lihe Road, Xinzhan District, Hefei City. It is a high-tech enterprise focusing on the circular economy of battery materials and new energy fields. The company's main business covers the complete industrial chain of the recycling of retired lithium battery materials, from recycling, dismantling, processing to sales, forming a closed-loop green circular economy system, but also through technological innovation and industrial upgrading, the company continues to improve the recovery rate and utilization rate of resources, and contribute to the cause of environmental protection. After years of development, Anhui Patrol Eagle Recycling Company has gradually grown into an enterprise with important influence in the field of battery material recycling economy and new energy. With advanced technology and perfect industrial chain layout, the company has made positive contributions to promoting green development and sustainable development.

Anhui Patrol Eagle New Material Technology Co., Ltd.Founded on May 11, 2022, with a registered capital of 50 million yuan, it is located in Hefei Circular Economy Demonstration Park, Feidong County, Hefei City, Anhui Province. It covers an area of 200 acres and has a total investment of 1.2 billion yuan.

Anhui Patrol Eagle New Material Technology Co., Ltd., as a high-tech enterprise engaged in new energy materials, closely follows the market development trend, meets the diversified needs of customers, and has established a more comprehensive lithium battery material research and development, production and sales system. The company is currently under active construction and is expected to be put into production by the end of 2024. It can simultaneously produce 3600 tons of lithium battery cathode materials, 2000 tons of lithium carbonate and a planned annual output of 200000 tons of new energy power battery materials recycling projects. Build a mechanism of ecological aggregation, full closed-loop development and global layout of the whole industrial chain from "material end-battery end-client-recycling end" to realize the recycling and recycling of resources, build a green and low-carbon circular industrial chain base, and promote the low-carbon demonstration effect of "green, low-carbon, digital and intelligent" to the world.

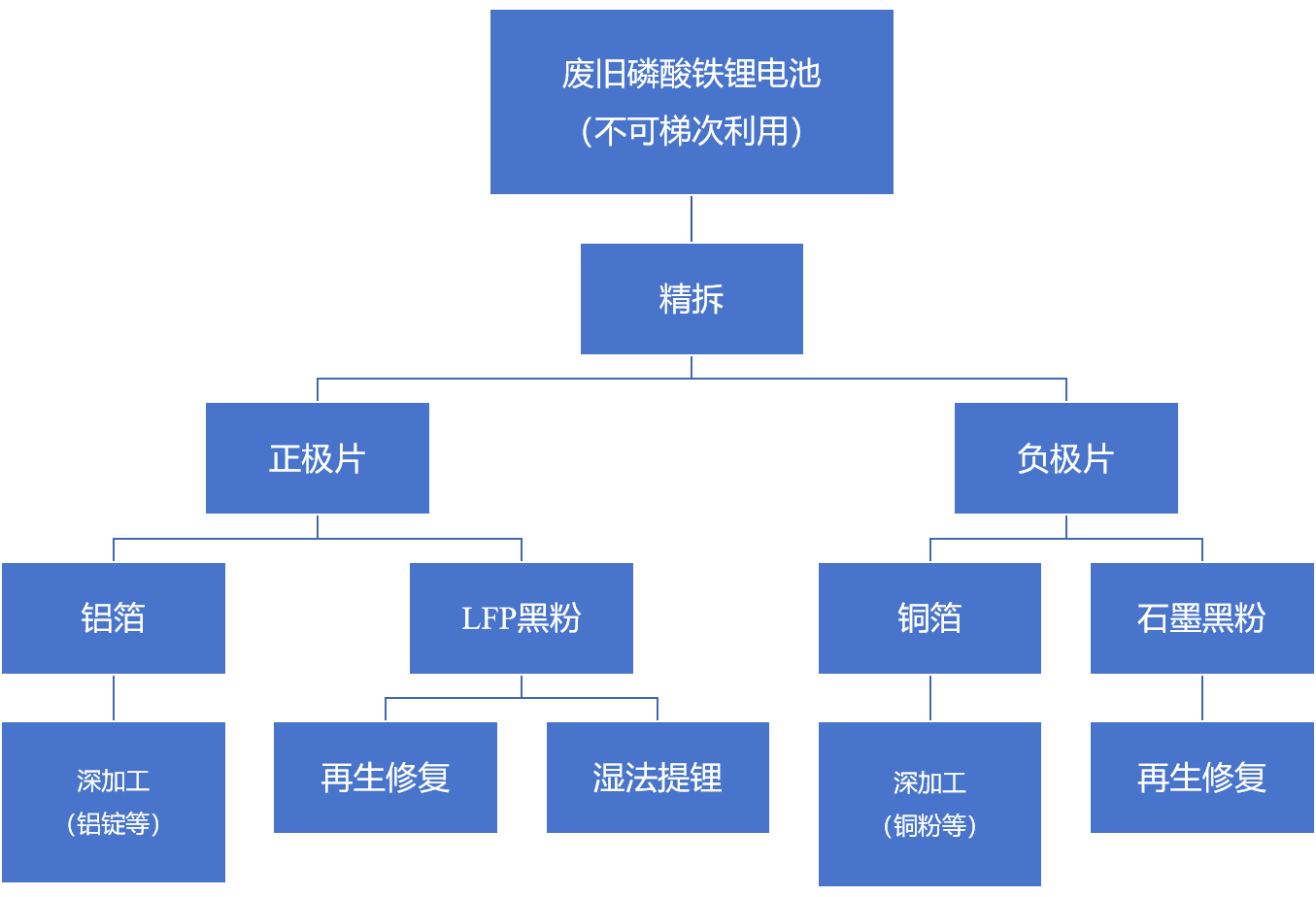

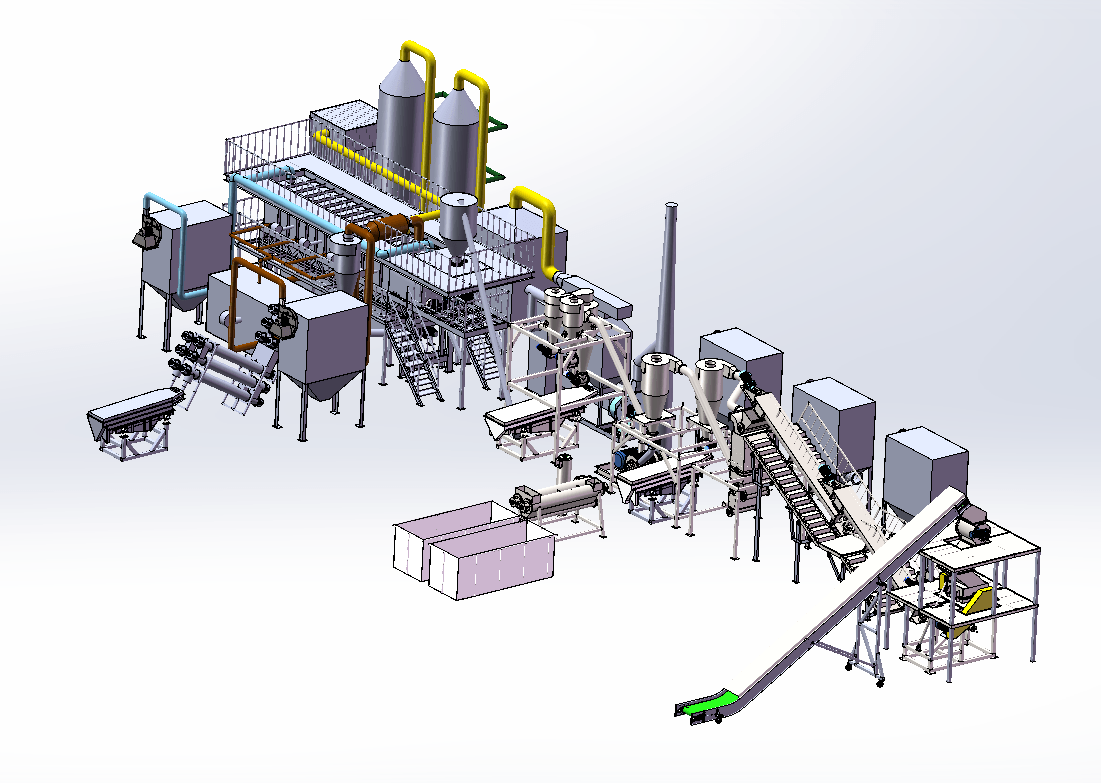

Recycling process

recovery process(Only part of the process is shown)

|

|

|

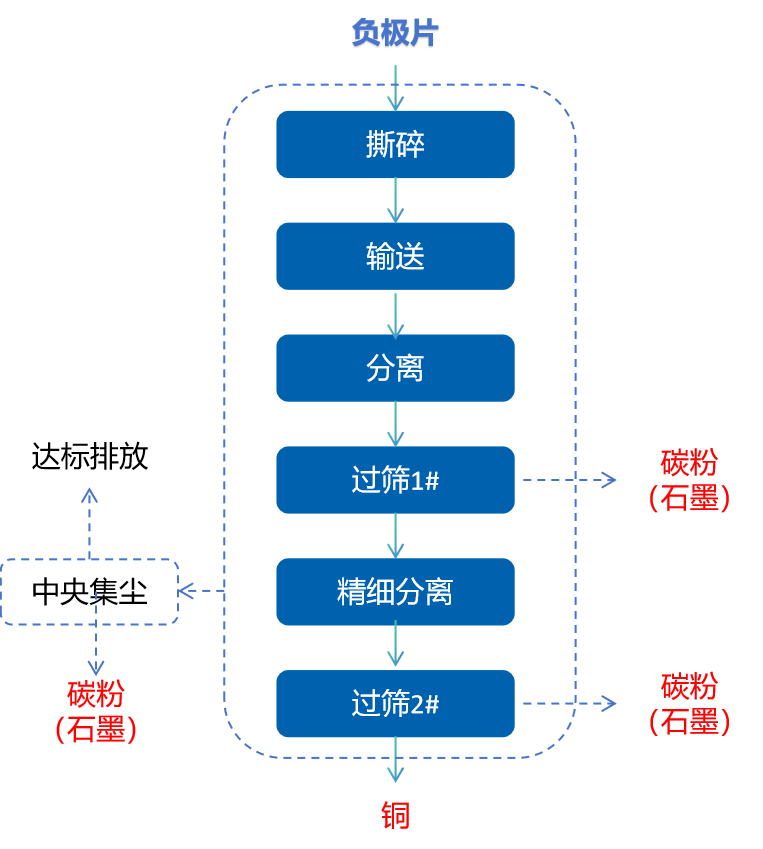

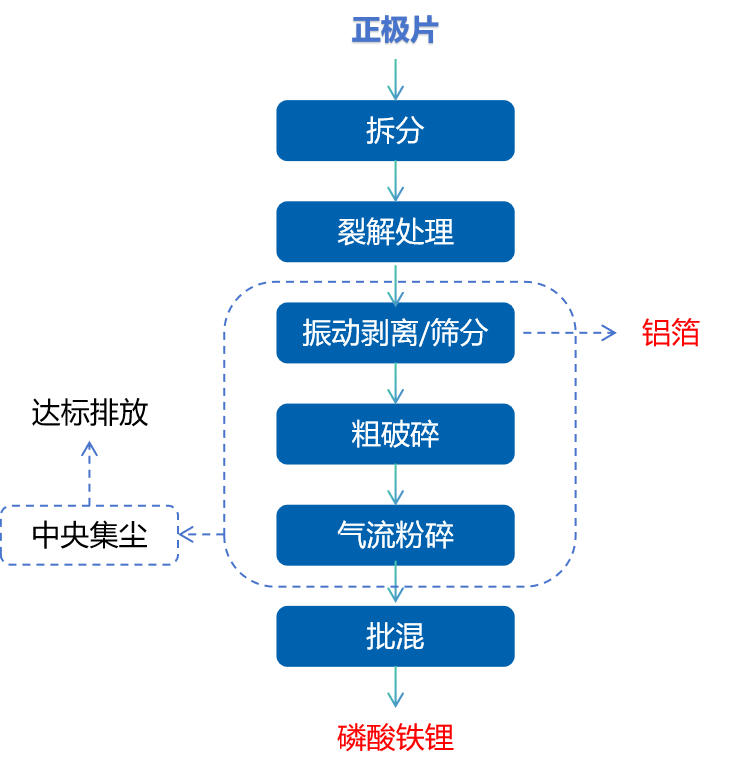

| Negative electrode de-powder process | Cathode de-powder process |

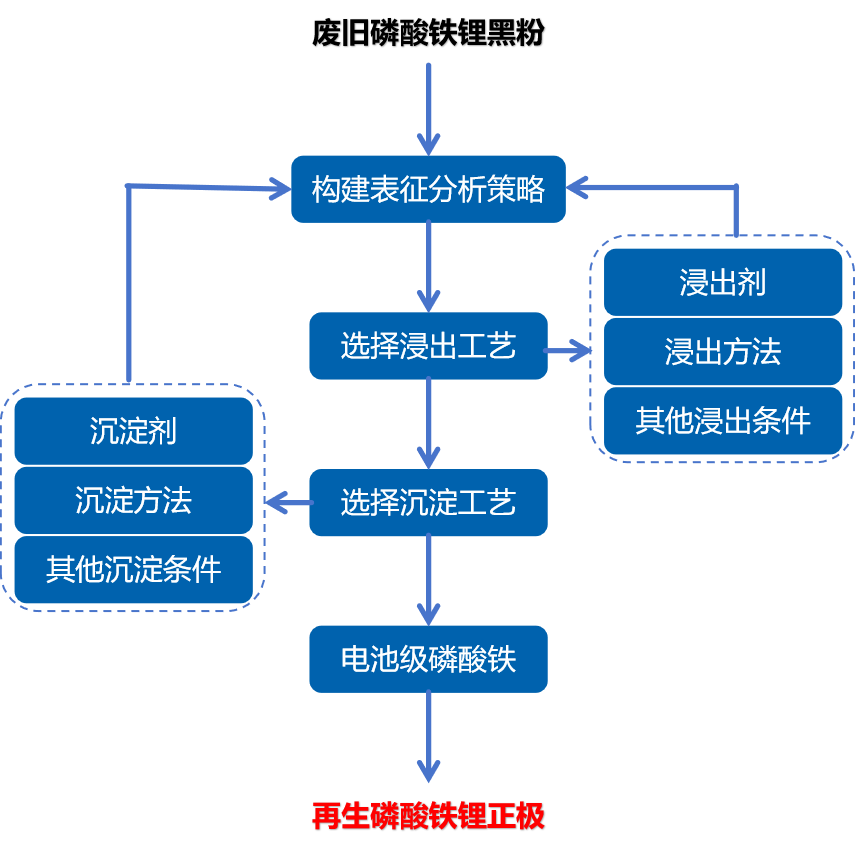

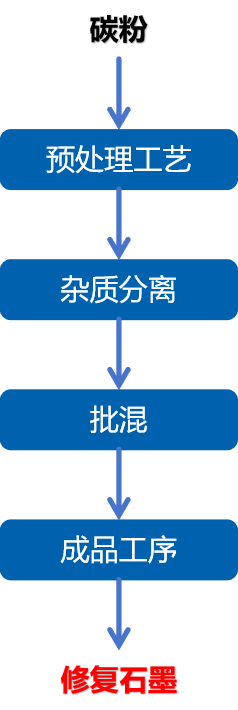

Repair process(Only part of the process is shown)

|

|

|

||

| Lithium iron phosphate repair process | graphite repair process | wet lithium extraction process |

Core Technology

With the rapid development of new energy industry, lithium battery as the core power source, its performance and life directly affect the operation efficiency and cost-effectiveness of the whole system. However, lithium batteries will inevitably have problems such as capacity attenuation and internal resistance increase during use, resulting in battery performance degradation and even failure.

Therefore, the repair technology of positive and negative materials for lithium batteries has become an important research direction to extend the service life of batteries and promote the recycling of resources. The following is a detailed overview of our current core technology for lithium battery positive and negative materials repair.

1. The method of micro-current charge and discharge cycle is used to activate the active material passivated by long-term shelving or improper use, and restore its original electrochemical reaction activity.

2. The positive and negative electrode sheets of lithium batteries usually contain a variety of materials such as active substances, conductive agents and binders. In order to obtain high-quality battery materials or carry out efficient battery recycling, it is necessary to de-powder the positive and negative electrode sheets, that is, to effectively separate the active material and other powders on the positive electrode sheet. At present, our company has mastered advanced physical and chemical depowdery methods, such as high-temperature cracking, new chemical additives and other technologies, which can efficiently complete depowdery separation.

3. The physical and chemical reactions under high temperature conditions are used to anneal and recrystallize the material to optimize its structure, reduce internal stress and improve material stability. Appropriate heat treatment can effectively improve the conductivity, ion mobility and cycle stability of the material, but too high temperature may lead to structural damage of the material, and the treatment conditions need to be strictly controlled.

4. Use the special properties of nanomaterials, such as high ratio table, strong activity, etc., to repair or modify the damaged electrode materials. By depositing nanoparticles, nanowires or nanofilms on the electrode surface, the number of active sites can be increased, the charge transport path can be improved, and the energy density and cycle life of the battery can be improved. In addition, the nano-repair technology can effectively inhibit the volume expansion of the electrode material and improve the safety of the battery,

In the process of repairing lithium battery positive and negative materials, environmental protection and safety are always the primary considerations. Our company through the use of green solvents, recycling and other ways to reduce the impact of the repair process on the environment. At the same time, through the design of explosion-proof devices, optimize the process, the implementation of strict safety management and other measures to ensure the safety of personnel and equipment.

Product display

|

|

|

|

|

| Aluminum Foil | copper foil | Graphite | lithium iron phosphate | Lithium carbonate |

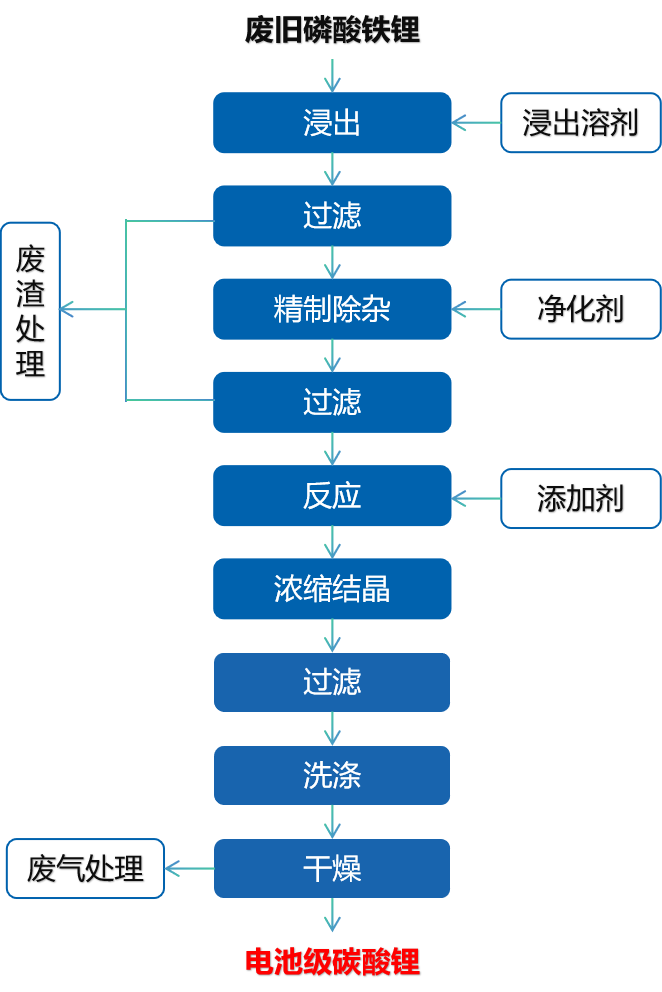

Equipment display

Dismantling Equipment for Lithium Iron Phosphate Battery (Network)

Previous Page

Next Page

Previous Page

Next Page